FAST PROTOTYPING

Rapid turnaround for your projects

CUSTOM SOLUTIONS

Tailored to your unique needs

24/7 SUPPORT

If you have any questions

BEST QUALITY

Many years on the market

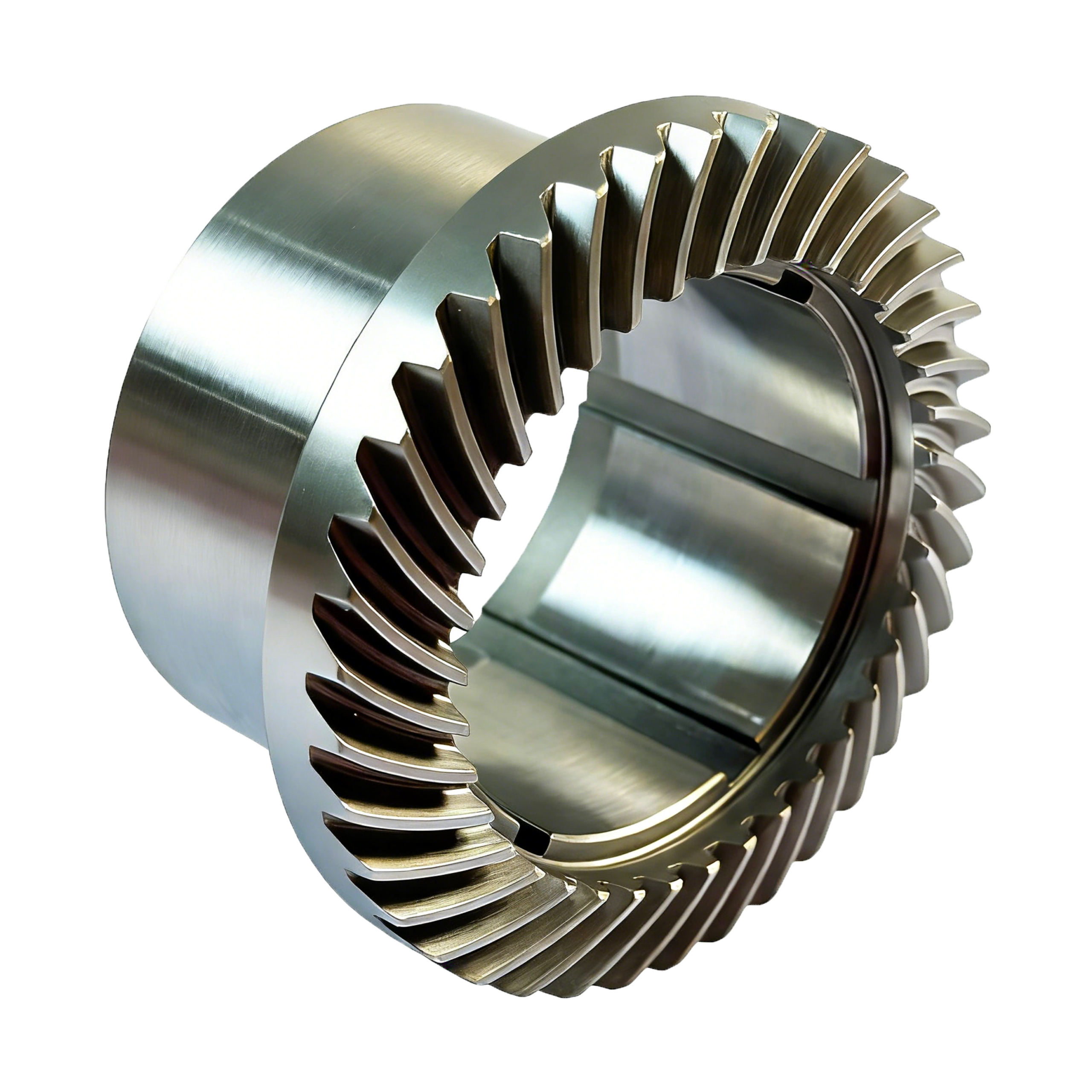

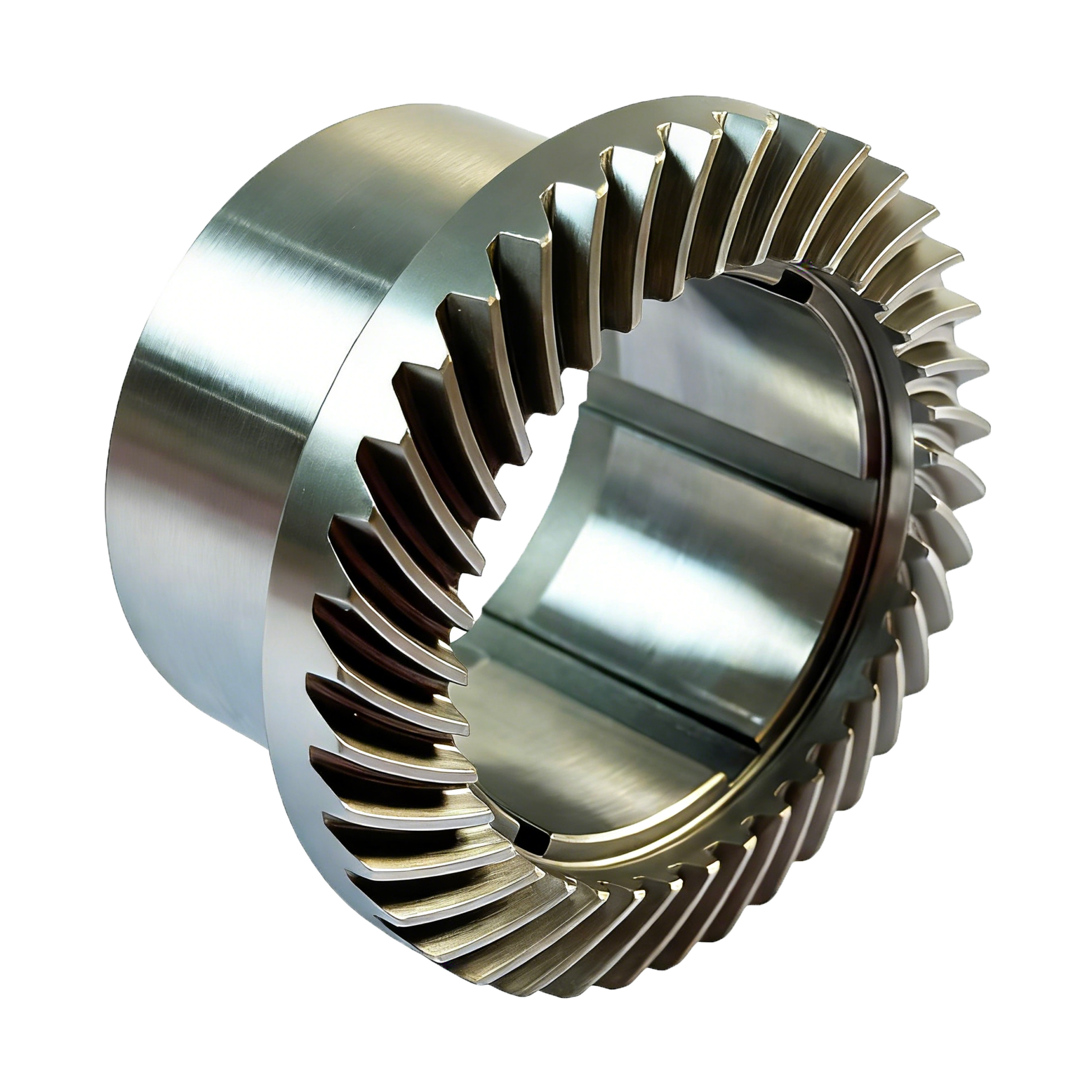

SCK50-2-2-02

$4.31 Piece

✅ Core Advantages: High-precision transmission, high load-bearing capacity, low noise, long service life, lightweight

✅ Key Parameters (SCK50-2-2-02): 20° Pressure Angle | 1.36 Modulus | 38 Teeth | 28°26′/R Helix Angle | 9mm Offset | 14mm Inner Diameter | 51.65mm Tooth Outer Diameter | 16mm Total Length | 0.1205kg Weight

✅ Exquisite Craftsmanship: Normalizing - Turning - Gear Milling - Heat Treatment - Chamfering - Shot Blasting - Reaming - Facing - Pairing Grinding - Marking - Full Inspection, Full-process Precision Control

✅ Application Scenarios: Power transmission for automobiles, construction machinery, precision instruments, automation equipment, etc.

✅ Product Features: High-quality alloy material | Precise meshing | Impact resistance | Low loss | Compliance with international industrial standards | Adaptation to high-load working conditions

32721.150020 Bevel Gear-32721.150010 Bevel Gear

$5.00piece

32721 series spiral bevel gears (including 32721.150020/32721.150010) are specially designed for sewing equipment. Made of 20CrMo, they are manufactured through full-process precision processes such as normalizing and turning + full appearance inspection. Core parameters: pressure angle 17°30′, module 1.05, helix angle 40° (right-hand/left-hand rotation respectively); Model 150020: 18 teeth, speed ratio 2, inner diameter 8mm, addendum diameter 21mm, weight 0.0118kg; Model 150010: 36 teeth, inner diameter 15mm, addendum diameter 38.33mm, weight 0.0428kg. Suitable for transmission of sewing equipment, with precise transmission, stability and durability.

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

BZ-008-C (50WF1-043 Hook Gear/341 Pinion) and BZ-009-C (50WF1-040 Lower Shaft/341 Gear Wheel) are exclusive supporting spiral bevel gears for 341 model sewing equipment. Both are made of 20CrMo and processed through multiple precision processes. Core parameters: pressure angle 20°, module 0.7, helix angle 36.393° (right-hand/left-hand rotation respectively); BZ-008-C: 16 teeth, speed ratio 2, inner diameter 7.94mm, addendum diameter 12mm, weight 0.0617kg; BZ-009-C: 32 teeth, inner diameter 9.5mm, addendum diameter 29.421mm, weight 0.0303kg. Used in supporting pairs, they feature precise and stable transmission, suitable for the transmission needs of sewing equipment.

6K – Upper Shaft Bevel Gear

$2.00piece

6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Left – Hand Rotation)and6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Right – Hand Rotation)

$2.00piece

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Left-Hand Rotation): A spiral bevel gear made of 20CrMo material with precise parameters and a speed ratio of 1. It is manufactured through multiple precision processes and suitable for the left-hand transmission needs of sewing equipment.

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Right-Hand Rotation): A spiral bevel gear made of 20CrMo material with sophisticated craftsmanship and stable transmission performance. It is a key component to meet the right-hand transmission needs of sewing equipment.

718WF14-025

$4.00piece

LCD859-1S Miniature Bevel Gear (Finished Product)

$1.00piece

6K – Upper Vertical Shaft Bevel Gear

$1.00piece

SPECIAL OFFERS

SCK50-2-2-02

$4.31 Piece

✅ Core Advantages: High-precision transmission, high load-bearing capacity, low noise, long service life, lightweight

✅ Key Parameters (SCK50-2-2-02): 20° Pressure Angle | 1.36 Modulus | 38 Teeth | 28°26′/R Helix Angle | 9mm Offset | 14mm Inner Diameter | 51.65mm Tooth Outer Diameter | 16mm Total Length | 0.1205kg Weight

✅ Exquisite Craftsmanship: Normalizing - Turning - Gear Milling - Heat Treatment - Chamfering - Shot Blasting - Reaming - Facing - Pairing Grinding - Marking - Full Inspection, Full-process Precision Control

✅ Application Scenarios: Power transmission for automobiles, construction machinery, precision instruments, automation equipment, etc.

✅ Product Features: High-quality alloy material | Precise meshing | Impact resistance | Low loss | Compliance with international industrial standards | Adaptation to high-load working conditions

32721.150020 Bevel Gear-32721.150010 Bevel Gear

$5.00piece

32721 series spiral bevel gears (including 32721.150020/32721.150010) are specially designed for sewing equipment. Made of 20CrMo, they are manufactured through full-process precision processes such as normalizing and turning + full appearance inspection. Core parameters: pressure angle 17°30′, module 1.05, helix angle 40° (right-hand/left-hand rotation respectively); Model 150020: 18 teeth, speed ratio 2, inner diameter 8mm, addendum diameter 21mm, weight 0.0118kg; Model 150010: 36 teeth, inner diameter 15mm, addendum diameter 38.33mm, weight 0.0428kg. Suitable for transmission of sewing equipment, with precise transmission, stability and durability.

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

BZ-008-C (50WF1-043 Hook Gear/341 Pinion) and BZ-009-C (50WF1-040 Lower Shaft/341 Gear Wheel) are exclusive supporting spiral bevel gears for 341 model sewing equipment. Both are made of 20CrMo and processed through multiple precision processes. Core parameters: pressure angle 20°, module 0.7, helix angle 36.393° (right-hand/left-hand rotation respectively); BZ-008-C: 16 teeth, speed ratio 2, inner diameter 7.94mm, addendum diameter 12mm, weight 0.0617kg; BZ-009-C: 32 teeth, inner diameter 9.5mm, addendum diameter 29.421mm, weight 0.0303kg. Used in supporting pairs, they feature precise and stable transmission, suitable for the transmission needs of sewing equipment.

6K – Upper Shaft Bevel Gear

$2.00piece

6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Left – Hand Rotation)and6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Right – Hand Rotation)

$2.00piece

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Left-Hand Rotation): A spiral bevel gear made of 20CrMo material with precise parameters and a speed ratio of 1. It is manufactured through multiple precision processes and suitable for the left-hand transmission needs of sewing equipment.

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Right-Hand Rotation): A spiral bevel gear made of 20CrMo material with sophisticated craftsmanship and stable transmission performance. It is a key component to meet the right-hand transmission needs of sewing equipment.

718WF14-025

$4.00piece

TECHNICAL SPECIFICATIONS

GEAR MODULE

Precision small-module gear / module range: 0.5–2.0 mm

(suitable for embroidery machines, reducers)

MATERIAL

High-strength alloy steel / surface treatment: carburizing & quenching

GEAR PRECISION

ISO 1328 standard / grade: 6–7

(ensures low-noise & stable transmission)

TRANSMISSION TORQUE

Max continuous torque: 15–50 N·m

(adjustable based on gear size & material)

SERVICE LIFE

Wear-resistant design / service life: ≥ 10,000 hours

(under rated load & proper maintenance)

CUSTOMIZATION RANGE

Customizable: tooth number, helix angle, bore size

(supports drawing-based one-stop customization)

GEAR COMPANY JINYI

ACCESSORIES

SCK50-2-2-02

$4.31 Piece

✅ Core Advantages: High-precision transmission, high load-bearing capacity, low noise, long service life, lightweight

✅ Key Parameters (SCK50-2-2-02): 20° Pressure Angle | 1.36 Modulus | 38 Teeth | 28°26′/R Helix Angle | 9mm Offset | 14mm Inner Diameter | 51.65mm Tooth Outer Diameter | 16mm Total Length | 0.1205kg Weight

✅ Exquisite Craftsmanship: Normalizing - Turning - Gear Milling - Heat Treatment - Chamfering - Shot Blasting - Reaming - Facing - Pairing Grinding - Marking - Full Inspection, Full-process Precision Control

✅ Application Scenarios: Power transmission for automobiles, construction machinery, precision instruments, automation equipment, etc.

✅ Product Features: High-quality alloy material | Precise meshing | Impact resistance | Low loss | Compliance with international industrial standards | Adaptation to high-load working conditions

32721.150020 Bevel Gear-32721.150010 Bevel Gear

$5.00piece

32721 series spiral bevel gears (including 32721.150020/32721.150010) are specially designed for sewing equipment. Made of 20CrMo, they are manufactured through full-process precision processes such as normalizing and turning + full appearance inspection. Core parameters: pressure angle 17°30′, module 1.05, helix angle 40° (right-hand/left-hand rotation respectively); Model 150020: 18 teeth, speed ratio 2, inner diameter 8mm, addendum diameter 21mm, weight 0.0118kg; Model 150010: 36 teeth, inner diameter 15mm, addendum diameter 38.33mm, weight 0.0428kg. Suitable for transmission of sewing equipment, with precise transmission, stability and durability.

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

BZ-008-C (50WF1-043 Hook Gear/341 Pinion) and BZ-009-C (50WF1-040 Lower Shaft/341 Gear Wheel) are exclusive supporting spiral bevel gears for 341 model sewing equipment. Both are made of 20CrMo and processed through multiple precision processes. Core parameters: pressure angle 20°, module 0.7, helix angle 36.393° (right-hand/left-hand rotation respectively); BZ-008-C: 16 teeth, speed ratio 2, inner diameter 7.94mm, addendum diameter 12mm, weight 0.0617kg; BZ-009-C: 32 teeth, inner diameter 9.5mm, addendum diameter 29.421mm, weight 0.0303kg. Used in supporting pairs, they feature precise and stable transmission, suitable for the transmission needs of sewing equipment.

6K – Upper Shaft Bevel Gear

$2.00piece

6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Left – Hand Rotation)and6K – Lower Vertical Shaft & Lower Shaft Bevel Gear (Right – Hand Rotation)

$2.00piece

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Left-Hand Rotation): A spiral bevel gear made of 20CrMo material with precise parameters and a speed ratio of 1. It is manufactured through multiple precision processes and suitable for the left-hand transmission needs of sewing equipment.

- 6K- Lower Vertical Shaft & Lower Shaft Bevel Gear (Right-Hand Rotation): A spiral bevel gear made of 20CrMo material with sophisticated craftsmanship and stable transmission performance. It is a key component to meet the right-hand transmission needs of sewing equipment.

718WF14-025

$4.00piece

NEW PRODUCTS

-

SCK50-2-2-02

$4.31 Piece

SCK50-2-2-02

$4.31 Piece

-

32721.150020 Bevel Gear-32721.150010 Bevel Gear

$5.00piece

32721.150020 Bevel Gear-32721.150010 Bevel Gear

$5.00piece

-

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

50WF1-043 Hook Gear (341 Pinion)and50WF1-040 Lower Shaft (341 Gear Wheel)

$5.00piece

NEW PRODUCTS

-

T16 φ5 Custom-made for Yinxiang and T16 Custom-made for Yinxiang φ7

$2.00piece

T16 φ5 Custom-made for Yinxiang and T16 Custom-made for Yinxiang φ7

$2.00piece

-

516WF7-004D and 516WF7-013

$3.50piece

516WF7-004D and 516WF7-013

$3.50piece

-

2020692 Shaft

$1.00piece

2020692 Shaft

$1.00piece

NEW PRODUCTS

-

Z-91-188080-15 Gear and Z-91-188032-15 Gear

$4.60piece

Z-91-188080-15 Gear and Z-91-188032-15 Gear

$4.60piece

-

Z-91-380787 Driven Gear

$13.00piece

Z-91-380787 Driven Gear

$13.00piece

-

531.06-78 45° Helical Gear (Driven) and 531.06-77 45° Helical Gear (Driving)

$3.50piece

531.06-78 45° Helical Gear (Driven) and 531.06-77 45° Helical Gear (Driving)

$3.50piece

NEW PRODUCTS

-

CJBB002F-1 (5-hole outer diameter non-turned) Finished Product

$1.00piece

CJBB002F-1 (5-hole outer diameter non-turned) Finished Product

$1.00piece

-

D-91-171401-15\Gear

$1.00piece

D-91-171401-15\Gear

$1.00piece

-

7J10105 Pinion

$1.00piece

7J10105 Pinion

$1.00piece

OUR LATEST ARTICLES

12

1 月

Hypoid Gears: Everything You Need to Know About This Bevel Gear Variant

-

Posted by

18852408117@163.com

- 0 comments

When it comes to power transmission systems, bevel gears are a staple in countless industrial and automotive applications. Among the va...

12

1 月

Helical Gears: The Ultimate Guide to This Cylindrical Gear Powerhouse

-

Posted by

18852408117@163.com

- 0 comments

In the world of cylindrical gears, helical gears stand out as a cornerstone of high-performance power transmission. Designed with angle...

Suzhou Jinyi Precision Gear Co., Ltd.

GEAR INDUSTRY INSIGHTS

Will be used in accordance with our Privacy Policy

Our precision gears drastically reduced the noise and downtime of our embroidery machines—transmission accuracy has stayed consistent even after 8,000+ hours of operation. The short-cycle customization service also helped us launch new equipment 2 weeks ahead of schedule.

Our team relies on Jinyi’s small-module gears for our robot transmission systems—their high precision cuts operational noise by 30%, and the 10,000+ hour service life has cut our maintenance costs significantly. The custom design turnaround was impressively fast too.

Robust gear designs power critical industrial workflows. Our precision-machined spur gears ensure consistent torque transfer, while our hardened tooth profiles resist wear in high-cycle applications. Every component is calibrated to tight tolerances, ideal for automotive drivetrains and manufacturing equipment.